Manufacturing Strategy

Manufacturing strategy is the set of choices about what the company will make (versus procure); where it will be made; how it will be made; and with what capabilities and capacities. It includes:

- What you manufacture versus source; and how you source components, modules, parts, raw materials — locally, regionally, centrally? Internally (from your other factories) or from other companies?

- Where you build (footprint; including scale, number, concentration of plants); diversity / homogeneity of manufacturing capabilities; flexible or dedicated capacity?

- How you build — manufacturing capabilities and processes; automation; process standardization; modular or integral manufacturing; how you schedule (batch, continuous)

Together, these choices deliver your manufacturing configuration: what product types, models, modules, components, and parts are produced in which factories; and whether that production is spread across regions; concentrated in the regions where each product is sold; or networked, with some factories supplying others.

Modular Manufacturing Strategy (MMS)

Distributes module production over a network of factories to:

- Reduce production cost

- Increase flexibility (make a wider range of product variants and volumes with the same assets)

- Improve resilience to price shocks and production disruptions

Modules are subassemblies with standard dimensions and interfaces which are combined to assemble the final product. End products can be partially or completely modularized. Product variants can be produced by changing out modules, instead of requiring different integral designs.

Modular Manufacturing Strategy is a paradigm shift from standalone factories and supply bases to a network of factories making parts and supplying modules to each other for final assembly.

Even if every factory completes final assembly of some products, some capital-intensive or difficult processes can be completed in two or three locations, instead of at every factory or supply base. Locations with lower costs for certain activities can do relatively more of those things for the network, so a higher proportion of production is done in lower cost factories. By concentrating some work in a few locations (instead of all), more benefits of scale and focus can be realized.

If production capabilities are geographically distributed, the production network is also more resilient to disruptions and cost shifts.

Client Engagement Examples

Global Modular Manufacturing Strategy

SITUATION:

This F50 company manufactures very large and expensive durable goods in numerous factories around the globe. Having already moved to modular product design, they wanted to explore ways to make use of that modularity to improve the flexibility, quality, cost effectiveness and efficiency of their sprawling manufacturing network.

SOLUTION:

We worked closely with executives and an operational core team to:

- Establish, define, and measure the key parameters to balance, including: cost, quality, risk and flexibility

- Determine and acquire key inputs such as product data, labor costs, tariffs, exchange rates, shipping rates, production costs, component/raw material supply costs, and many more

- Provide design and operationalization assistance for a comprehensive multi-variant optimization model

- Develop target scenarios and iteratively model both the financial and non-financial impacts of each scenario

- Assess results and recommend “optimal” global manufacturing network – including dramatic changes in product modularity and manufacturing footprint

RESULT:

The new manufacturing strategy – currently being implemented – is projected to save hundreds of millions of dollars in operational costs, while increasing network flexibility and reducing risk. The optimization model is now being used in other business lines across the company.

Manufacturing Strategy for Growth

This company was facing explosive growth and needed to expand capacity in order to meet market demand. They needed to determine in what locations to manufacture which products/components, incorporating numerous factors, including: current and future customer demand by region, location of current facilities, geographic labor conditions/costs, governmental stability, infrastructure costs, supply chain, etc.

SOLUTION:

We worked closely with executives and an operational core team to:

- Determine a workable approach and objectives given an aggressive business strategy

- Develop the numerous factors critical to the decision-making process and determine a set of viable candidate scenarios

- Model the financial and assess the non-financial factors for each scenario

- Decide on the optimal scenario/variants and formulate a strategy, including elements cost, risks and associated critical success factors

RESULT:

The strategy was implemented throughout Europe and Asia, generating significant profitable growth — the company returned record results within two years.

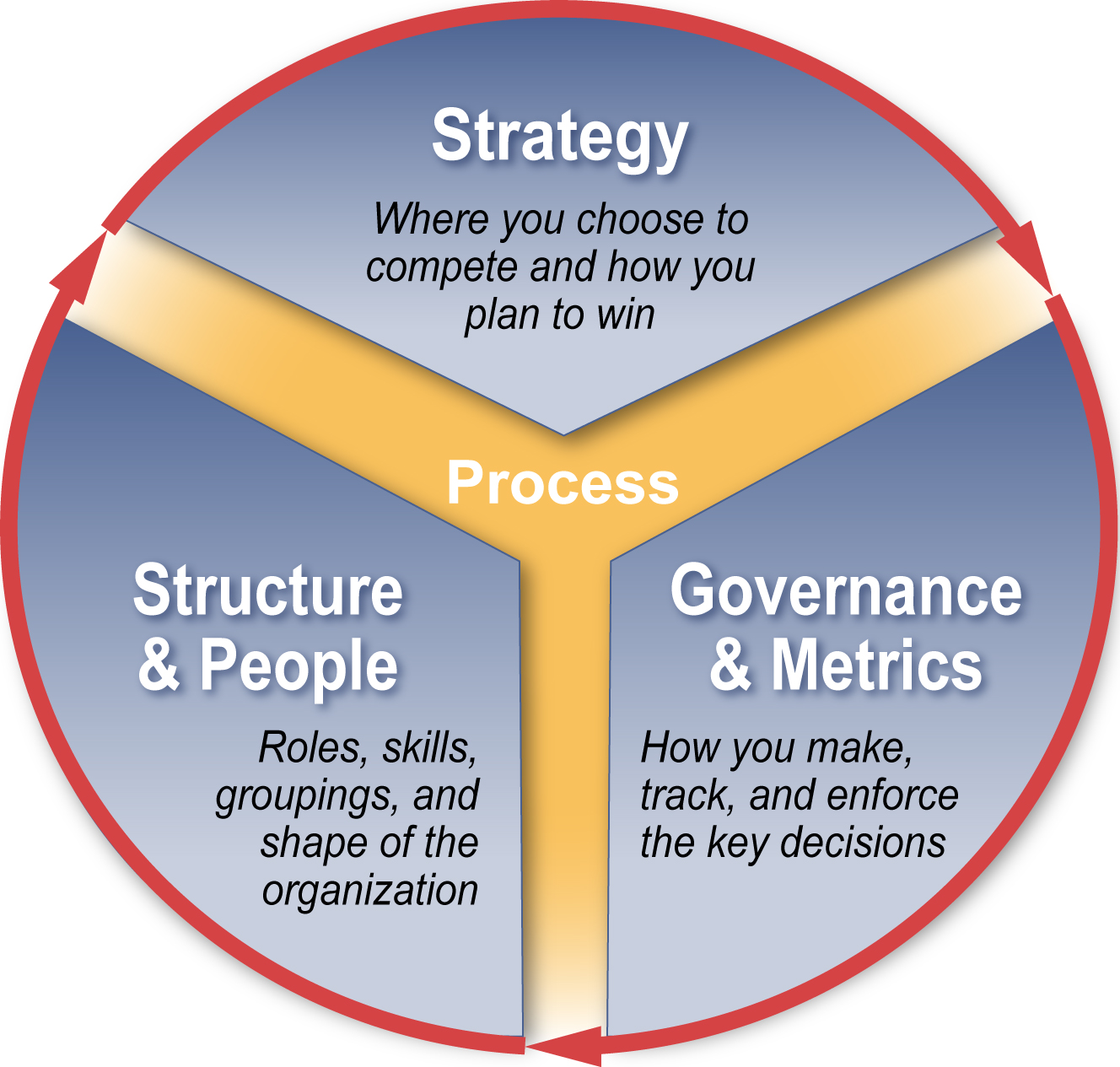

Outputs, capabilities and tradeoffs in manufacturing strategy

The configuration of production assets is what gets most attention, but real capabilities result from not only the configuration of assets but the skills & knowledge (in people) to operate them and the organizational processes that guide how those people interact. A manufacturing strategy needs to define the appropriate mix of capabilities — consistent with the business strategy. Changes in the market environment as well as the business strategy can affect what should be the appropriate balance across capabilities. And always there are tradeoffs.

Manufacturing Capabilities

Flexibility

There are several dimensions to flexibility, such as:

Agility & Responsiveness

The ability to handle changes in production volumes or product mixes; and to react quickly and effectively to product design changes, raw material changes, or customer order and delivery requirements (product options, order changes, delivery modes / timing / locations)

Resilience

The ability to withstand shocks or rapid changes in exchange rates, labor or input costs, trade conditions, shipping rates, pandemics, and other operational disruptions

Integration

The ability to incorporate new processes, products, or product architectures into the manufacturing operation

Innovation

The ability to develop and deploy new or unique manufacturing processes to dramatically improve manufacturing performance

Control & Improvement

The ability to direct and regulate operating processes, correct errors or inefficiencies, and to improve manufacturing performance

“During times of relative stability, manufacturing strategy focuses on getting better at the things necessary to defend the position staked out in your business strategy. In turbulent times, manufacturing strategy is about flexibility.”

— “Beyond World Class: the New Manufacturing Strategy,” Harvard Business Review

What Manufacturing Configuration Yields:

Production Cost

A manufacturing configuration delivers at a production cost. Achieving the targeted per unit delivered cost is a key driver of how you configure your production assets, but this must take into account constraints on:

- Factory and supply chain capital: better tooling and more automation can often reduce manufacturing costs, but factory capital (or support for suppliers) is usually limited. A crucial determinant of these capital requirements is desired capacity — which puts pressure on demand forecast accuracy.

- Development capital: a better design may be less costly to manufacture, but better designs are not costless

Capacity Profiles & Production Rates

- Any particular configuration has a set of capacity profiles: how many units of each type can be produced, and how much capacity can be swung from one product to others.

- For each capacity profile, there is a maximum production rate for each product.

Product Quality

Defining and reaching the appropriate quality levels can be difficult and costly, depending on what those levels are — which are driven by the business strategy and the competition. In deciding where to build what, you may also need to consider perceived quality — the value your customers may place on the “made in X” label. This can drive strategies which assemble in destination markets, but of components imported from elsewhere.

Delivery / Fulfillment

Major dimensions include:

- Speed — from the time of order, how fast can it be delivered to the customer?

- Accuracy — delivering the expected product when it was committed

Manufacturing Strategy in Context:

Manufacturing strategy is also affected by — and in return affects — other functional strategies:

Marketing & Sales

What you want to sell to whom, and where:

- How you define markets (segmentation) and identify opportunities relative to competition

- How you brand

- What product & service capabilities are needed to win in targeted segments

Product Development

How you design & engineer to deliver the needed product / service capabilities:

- Technologies, design platform, modularization

- Specifications (for features, quality, performance)

- DFSS, DFManufacturability, DFServiceability

Order Fulfillment

Order Fulfillment (OF) is a coordinated process connecting:

- Forecasting (plan the order)

- Selling (get the order)

- Supply management (acquire the material required)

- Manufacturing (make what’s ordered)

- Outbound logistics (deliver the order)

- Invoice & collect (get the order paid for)

OF processes must be able to accommodate differences in Sales or Manufacturing strategies and priorities across geographies, product lines, and customer segments.

Supply Chain & Logistics

Supply Chain Management & Logistics (into & between plants) must bridge the needs of Engineering and Manufacturing to:

- Develop the supply base in each location and globally…

- For RM, parts, components, and modules…

- To meet specs…

- And get the right inputs to the right places at the right time

Any of these elements may need to change due to new competitors, changed regulations, different input costs, new technologies, or any of the other myriad ways the business environment is continuously evolving. That doesn’t mean they all must change or that they must change together — successful companies carefully evolve as the environment changes, and we can enter in any of these practice areas to begin to make improvements.

We employ distinctive techniques (such as business wargaming and organizational simulations) across all our practice areas, as well as proprietary frameworks and processes.