If you Google manufacturing strategy, one of the top results is a Harvard Business Review article — from 1994. How can it rank so high given its vintage? The reason: it gets clicked on a lot — not only because it was written by two authorities on the subject, but because its insights remain on-point and highly useful (even after twenty-five years).

Let’s start with what they say about manufacturing strategy and strategic flexibility. Hayes & Pisano argue that:

In a stable environment, competitive strategy is about staking out a position, and manufacturing strategy focuses on getting better at the things necessary to defend that position. In turbulent environments, however, the goal of strategy becomes strategic flexibility. Being world-class is not enough; a company also has to have the capability to switch gears—from, for example, rapid product development to low cost—relatively quickly and with minimal resources. The job of manufacturing is to provide that capability.

That seems like kind of a big ask, doesn’t it? Perhaps it’s less daunting if we break it down into manufacturing capabilities that can deliver strategic flexibility to the business, such as:

- Agility & Responsiveness — the ability to handle changes in production volumes or product mixes; and to react quickly and effectively to product design changes, raw material changes, or customer order and delivery requirements (product options, order changes, delivery modes / timing / locations)

- Resilience — the ability to withstand shocks or rapid changes in exchange rates, labor or input costs, trade conditions, shipping rates, pandemics, and other operational disruptions

- Integration — the ability to incorporate new processes, products, or product architectures into the manufacturing operation

- Innovation — the ability to develop and deploy new or unique manufacturing processes to dramatically improve manufacturing performance

- Control & Improvement — the ability to direct and regulate operating processes, correct errors or inefficiencies, and to improve manufacturing performance

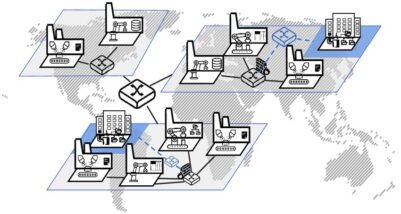

Such capabilities depend on much more than manufacturing sites, equipment and technology. As Hayes and Pisano point out, “a company’s capabilities are more than its physical assets. In fact, they are largely embodied in the collective skills and knowledge of its people and the organizational procedures that shape the way employees interact.”

Assembling the right combinations of assets, people, and process to deliver a desired capability — such as resilience to trade disruptions or global pandemics — takes time, commitment, and judgment.

And of course there are tradeoffs: low-cost production which relies on offshore suppliers can be brittle, subject to supply shocks (as many learned during the pandemic); yet steps to increase resilience can also increase costs. Production agility, if achieved with highly flexible lines, can also be expensive (but there are other ways to do it…).

These choices should be made in view of the business strategy — particularly the “how to win” elements. And good decisions about how to win can’t be made in ignorance of the actual or potential capabilities of the manufacturing organization. In fact, by “expanding the range of their manufacturing capabilities, [manufacturing leaders] increase their strategic options” for the business.

Which is why manufacturing leadership should be engaged in the business strategy.